-40%

Yakovlev 52, Pitot Tube Stabilizing Shroud

$ 42.82

- Description

- Size Guide

Description

Next time you’re at the hangar, take a look where your Yak 52’s Pitot tube exits the port wing.The Pitot tube either has some form of support where it passes through the wing leading edge - or it doesn’t.

The factory Pitot assembly actually attaches to a wing rib about 7” back from the Leading edge - and with that heavy steel heater head, all the way out in the airstream on the end of a slender aluminum tube, it’s a huge vibrating cantilever.

The unavoidable gap between the hole in the leading edge sheet metal and the pitot tube passing through would have originally been doped over with a small piece of fabric to restrict movement - good enough if you’ll be back in the overhaul factory every 500 hours.

But it’s your plane now - and if you’ve ever been in cruise and looked over to see your gyrating pitot tube (pleading with you to get the prop balanced), you’re also watching its fatigue life ebbing away at that hidden joint inside the wing.

More trivia: if you look at the underside of your wing and see an inspection port…that wasn’t there when it left the factory. A repair facility had to cut that access hole to….repair a broken pitot.

Short version? Stabilize that pitot / leading edge skin joint without delay!

These days nearly everyone knows somebody with a 3D printer. That cottage industry’s little secret though, is that these inexpensive printers nearly all use filament technology with one of two low melting temperature, low strength resins (: PLA or ABS by name)

By contrast, using the Selective Laser Sintering process, this part is made of white Nylon 12 which will survive weather, vibration and stress.

Plus the shroud is removable- (unlike some sheet metal welded variants or tired mastic you’ll see out there).

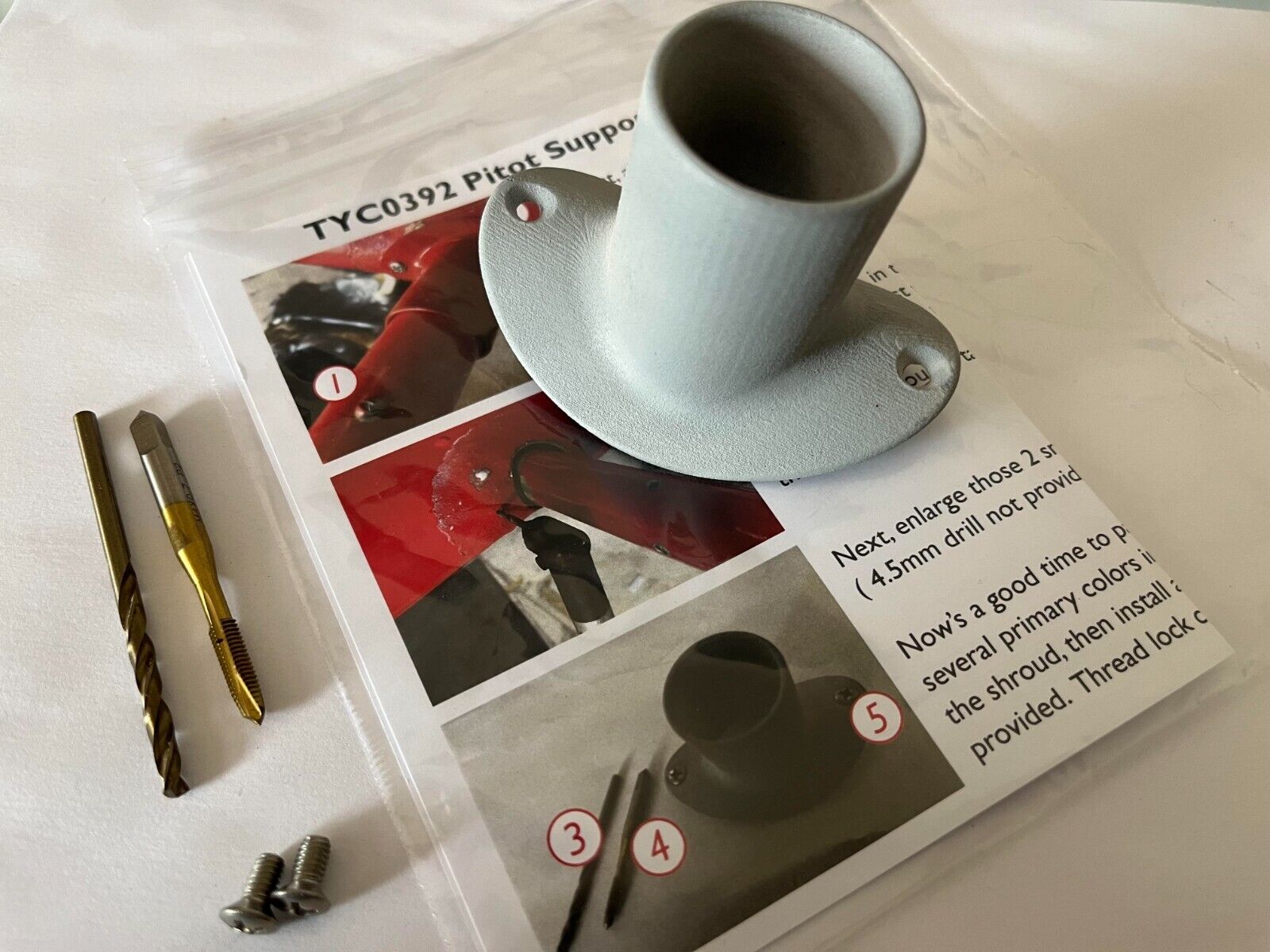

You’ll need to remove seven (very easy to lose) slotted head screws with washers, of two different diameters and lengths, along the length of pitot tube - then slide your painted Nylon shroud over the Pitot tube, noting the gentle sweep back angle of the leading edge incorporated into the design.

The 2 molded holes in the shroud are the correct tap drill size for M4x.7, so seat the shroud against the leading edge and use it as a template (using the 3.3mm drill provided ) for two tap drill holes through the wing leading edge,

Then, remove the shroud & tap these two holes. ( M4x0.7 tap included) into the leading edge sheet metal.

Next, enlarge those 2 small holes in the shroud up to 4mm clearance ( drill not provided - but if you own a 11/64” drill - that will do fine)

The Shroud has been sprayed with High Solids Epoxy primer and buffed with 800 grit, so it's ready for paint. Your local auto parts store may have aerosol cans of paint in several colors, expressly for plastic surfaces.

Secure and tighten the 2 M4 Phillips head countersunk screws provided. Thread lock compound is recommended. Replace the pitot fastening screws you removed earlier - and the job is done.

A stitch in time…saves not only a costly repair but perhaps inflight loss of airspeed indication.

Worth a few bucks?

You decide.

Kit inlcudes:

1 Nylon shroud, printed installation instructions, 1 drill, 1 tap, 2 screws